Low fuel rail pressure is a very common issue we see on Duramax trucks. It is an issue that has an array of different degrees but can leave you stranded on the side of the road if not recognized and dealt with.

- Common symptoms of low fuel rail pressure are the following:

- Low power or engine power reduced message in driver information center (DIC)

- Change fuel filter message in driver information center (DIC)

- Poor transmission shifting operation

- Increased smoke output

- High exhaust gas temperatures (EGTs)

- Check engine light (CEL) P0087

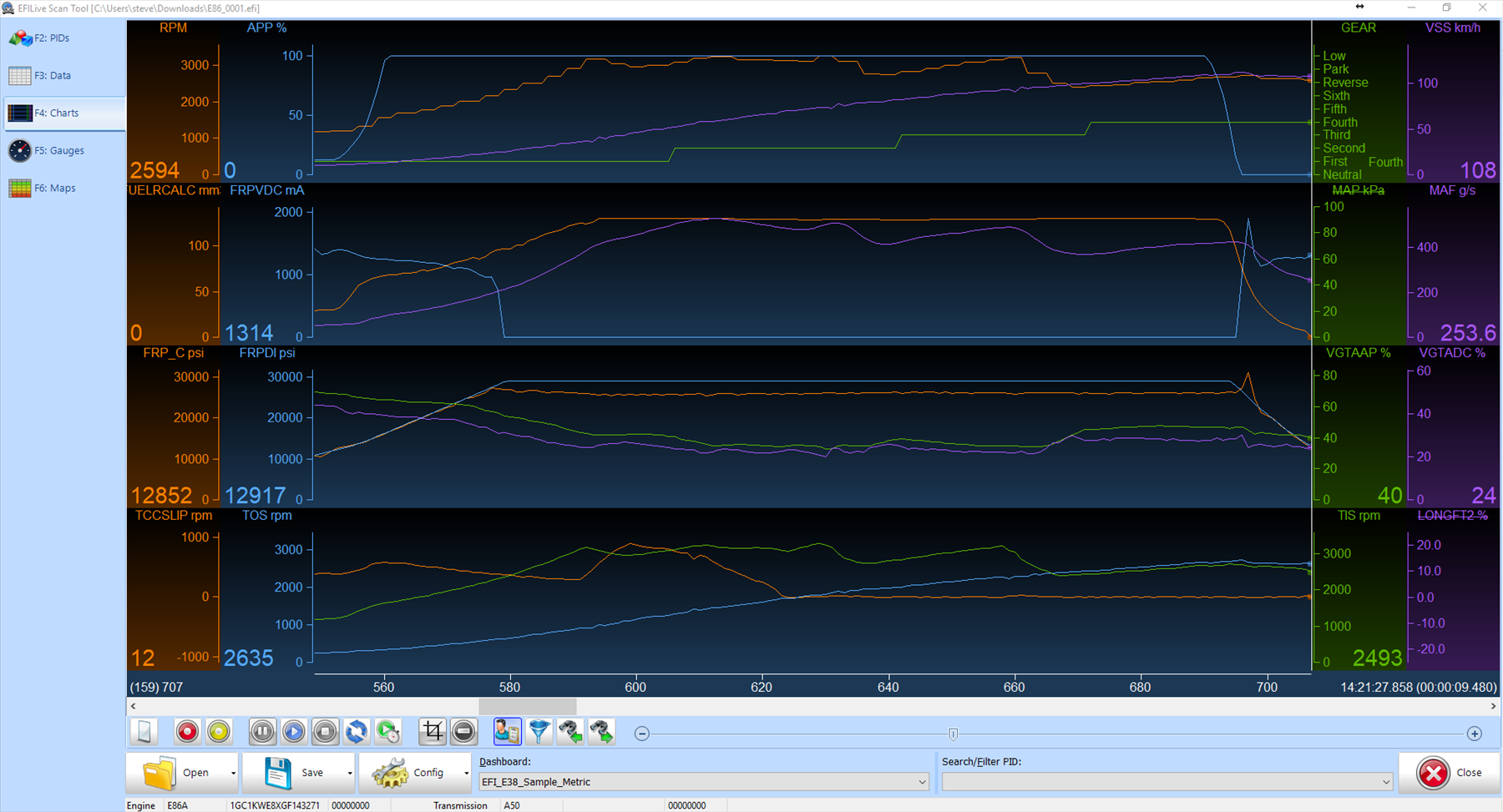

If you have any of the following symptoms it is time to dig in and data log the truck to see if you can watch the issue occur in real-time. On all tuning platforms that Motor Ops offers (EZLynk, EFILive, and Smarty MM3) you can monitor your engine’s PIDs in real-time, record, and send to a technician if need be. Below you can see a screen shot of a truck that was experiencing low fuel rail pressure.

The deviation between commanded rail pressure in this situation is ~5,000 PSI; this degree of low fuel rail pressure would be well known by the driver at WOT or when the truck is under load. However, it may go unnoticed under light operation. Either way it is an issue that needs to be addressed. Any consistent deviation between commanded and actual fuel rail pressure that is more than 1,500 PSI should be addressed immediately.

IMAGE

When addressing the issue you want to start with the cheaper and easier repairs and work your way up to the top. Here is a check list to follow:

- Change Fuel filter if it has not been changed recently (within the past 5,000 Miles).

- Inspect fuel lines from fuel filter to injection pump and from CP3 to fuel rails for any leaks or damage.

- Change your fuel pressure relieve valve to a Race Fuel Valve (solid valve replacement) The spring in the factory valve often wears out and can relieve pressure at a much lower pressure than it should.

- Check Fuel Pressure regulator on CP3 or CP4 for debris, CP4 failure can be easily detected with metal shavings on the regulator screen. Failure of this sort will require you to have all fuel system parts cleaned, pump replaced, and injectors tested or potentially replaced.

- Check or change CP3 or CP4 injection pump. This is about as bad as it can get but the pumps are parts that do wear over time. If you have done all of the above steps with no success at alleviating the low fuel pressure issue then it is very likely that you need to replace your injection pump.

Most fuel rail pressure issues can be avoided with routine maintenance, additional filtration (lift pump), and not ignoring minor issues. Keep your fuel filters clean and fresh, invest in a lift pump, keep a Race Fuel Valve handy, and purchase fuel at reputable sources to keep yourself from being stranded on the side of the road with low rail pressure issues.